KRISOL Tex Textile Industry is one of the leading industry in Indian economy.It includes Handlooms, woolen Textiles and Readymade Garments. The textile processes includes designing, Production, distribution and sales. In global context, the indian textile industry’s contribution is very significant. The production Includes both cotton yarn and fabrics along with synthetic fibres and yarns. As the ownership of Industry increases the owners of the units believe that ERP is not only essential but indispensible.

Features

Streamlines all the business processes.

Brings total transparency to the top management, Manipulation and human errors are eliminated.

Controls all the business operations.

Maintains the records of Customers, business Partners and Dealers.

Different textile mills in different locations can be managed easily.

Stock Transfer between warehouses for multi-location establishments.

Project wise accounting and costing gives excellent control over project cost and budgets.

Krisol ERP

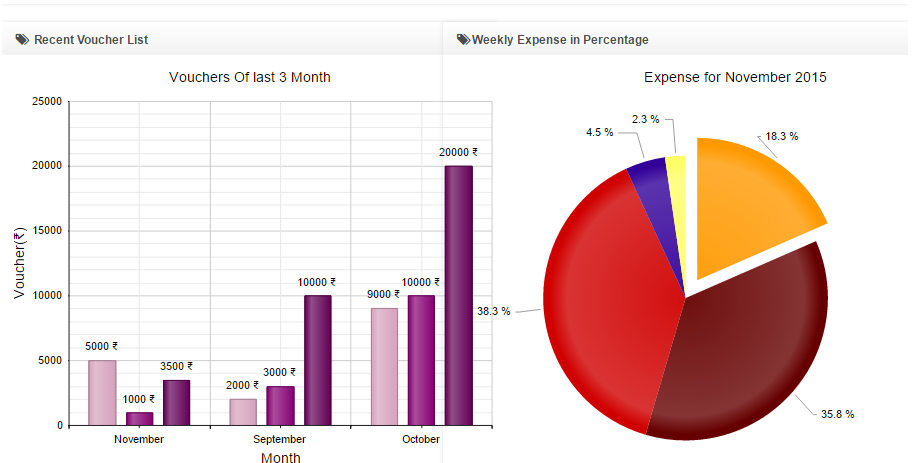

Krisol ERP (Enterprises Resources Planning) provides software-centric solutions to customers in the enterprise computing space .ERP helps you in Automating your working processes and monitoring different departments in your enterprise and its reporting services helps you in critical decision making by representing facts in graphs, charts etc With Krisol ERP you can control you business from any where in world.More customer friendly

We are Strong!

-

98% WordPress

-

88% Html & CSS

-

95% Javascript

-

90% Photoshop

-

60% Illustrator

-

94% Blender

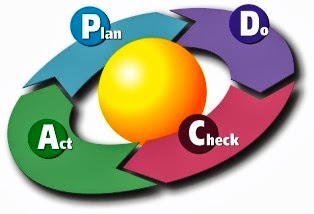

Planning and Production Management

Krisol ERP for planning and production manages all the business process for an organization. It supports various types of departments in the business. Based on the particular organizational needs the ERP system can be customized, thus providing the required services. Below are some of the functionalities or modules that come under the ERP system. Read More.

Supply Chain Management

Price competition and fluctuation in customer demand is faced by the Manufacturers, suppliers, distributors and retailers. These challenges are to be handled efficiently by real- time visibility into the customer demands. Read More

Finance

Krisol ERP for planning and production manages all the business process for an organization. It supports various types of departments in the business. Based on the particular organizational needs the ERP system can be customized, thus providing the required services. Below are some of the functionalities or modules that come under the ERP system. Read More.

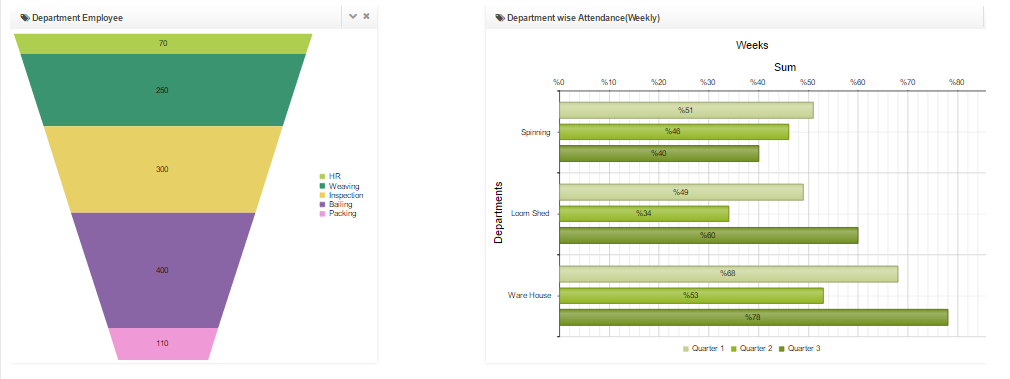

Human Resource Management & Payroll

Krisol ERP for Human Resource Management system maintains and helps in tracking the complete employee related information Read More

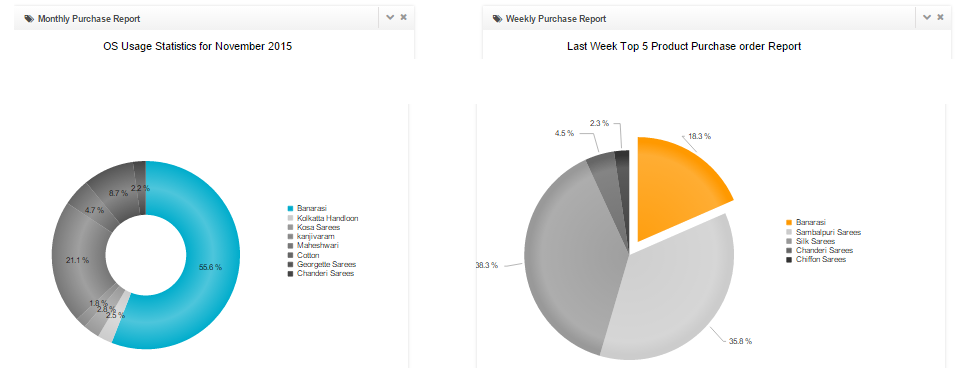

Distribution &Trading

Krisol ERP structuring distribution to ensure our clients' commercial objectives Read More.

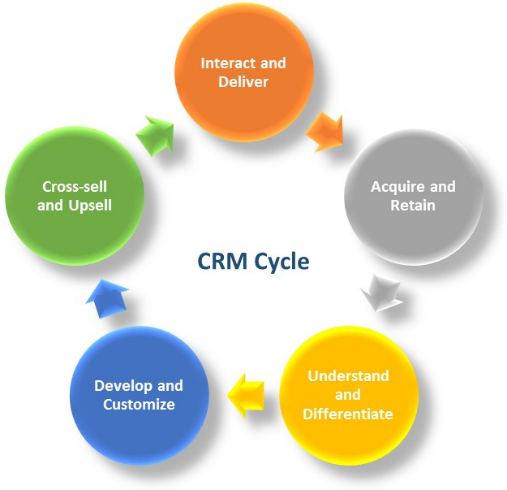

Customer Relation Management

Krisol CRM helps managing the details like sales activities, order details, customer information and quote for the sales order. It also includes details like order processing, Invoice. Customer Relation Management ERP also helps in improving the sales and marketing by keeping track the sales information. Read More

Retail Management

Retail Management System helps in improving sales by better understanding of the customer needs. The main focus is on the customer satisfaction. Below are few of the key principles of retail Management. Read More.

Responsive Design & Retina Ready

Responsive Design & Retina Ready

Ready for small, medium and double pixel screens!

Zap is 100% responsive,including all premium sliders and every features you wish to use with it. Zap contains a powerful Retina-Ready built on Font-Awesome Font and vector icons. Make astonishing layout pages with it and check between screen resolutions the perfect distinctness! Check it in your iphone.

4 Headers Layouts

Zap offers you variety. You choose your favorite.

You have 4 Different Options.

Premium Plugins Included

Zap come with 4 premium plugins

We included it on the package. Save 22$ all in one.

Unlimited Portfolios

Zap is the perfect theme to showcase you work.

We cover all styles. You choose your favourite.

55+ HTML5 Pages

55+ HTML5 Pages. Clean & Well Documented Code

Font Awesome Integration

More than 350 Icons for you use!

Font Awesome gives you scalable vector icons that can instantly be customized

Wide & Boxed Layout

Choose your style. Wide & Boxed Layout.